[In-person & Livestreamed event]

Electric vehicle batteries are a key technology for the EU’s decarbonisation and transition to clean mobility. As demand for lithium-ion batteries is expected to significantly increase in the coming years, building an EU industrial ecosystem for battery circularity can deliver both environmental benefits and economic value for the EU. While the new EU policy landscape is being reshaped with new frameworks such as the Batteries Regulation, the Critical Raw Materials Act and the Industrial Accelerator Act, questions remain about how to translate policy ambition into effective industrial ecosystems for batteries circularity.

This policy-focused event draws on lessons learned from the implementation of the BATRAW project to discuss current challenges and the necessary conditions for scaling up circularity applications for EV battery packs in the EU. Topics to be addressed include regulatory constraints, information and data gaps and market-related challenges affecting recycling and reuse operations across the battery value chain. The discussion will also highlight key enablers and policy instruments for creating the conditions for investment and innovation in battery circularity applications.

Organised in the context of the BATRAW EU-funded project the event will bring together stakeholders from the region (policy makers at different governance levels, industry stakeholders and civil society representatives) to exchange views on how EU and national policies can accelerate the deployment of circular battery solutions and support the EU’s decarbonisation goals.

What makes leaching and bioleaching truly work? The answer lies in reactor design. This webinar dives into the science behind mixing, mass transfer, and bioreactor performance – revealing how smart design decisions can boost extraction efficiency and sustainability. Drawing on insights from Horizon Europe projects, the webinar will discuss current research and emerging strategies addressing these reactor design challenges.

The next webinar from the METALLICO Webinar Series is coming up, and we are very happy to invite you to join us for the webinar entitled “How Reactors for Leaching and Bioleaching are working – Insights from research to practice”

The session will take place on 9th of March 2026 from 13:30-15:30 (CET).

The webinar will focus on the topic of reactor design for leaching and bioleaching. It will present scientific and technical perspectives from the European research projects METALLICO, RESPECT, Tetalead and XTRACT and discuss how current research contributes to more efficient and sustainable reactor designs.

The Cluster Hub “Materials for Batteries” took the stage at Battery Innovation Days 2025, contributing to the discussion about the strategic role of recycling in the EU Battery Regulation and the broader circular economy.

Presentations explained, one after the other, Europe’s alternatives to build a circular battery ecosystem. With electric mobility accelerating and battery demand soaring, recycling is no longer optional. It has become a strategic necessity for Europe’s competitiveness and climate goals. And the EU wasted no time to announce on 3 December its recent ReSourceEU Action Plan, under the headline “Accelerating our critical raw materials strategy to adapt to a new reality”. ReSourceEU places circularity at the core of EU’s approach to set the basis for competitive CRMs industry in Europe.

Eleonora Cali (RINA), representing the Materials for Batteries Cluster Hub in the parallel session “End of life, start of supply: Advancing battery recycling in Europe” on 2 December, joined leading experts to address two pressing realities in the battery industry:

- Europe’s dependency on imported raw materials. Lithium, cobalt, nickel, manganese and graphite are critical for the energy transition, yet supply chains remain dominated by non-European players. Recycling offers a way to keep these resources in Europe, reduce environmental impact, and comply with EU regulations on secondary raw material content. The European Commission’s new Battery Regulation aims to change that by mandating minimum recycled content for key materials from 2031. This is more than an environmental measure: it is an industrial policy designed to keep resources within Europe and reduce strategic dependency.

- the expected surge of end-of-life batteries. With EU speeding up its transition to electric mobility, the question of what happens to millions of batteries at the end of their lifetime is shifting from technical to strategic priority.

Surprisingly, speakers underlined EU’s anticipated timeline to develop recycling plants, with a scarce input of end of life applications. According to Andreas Opelt (Saubermacher) and Verena Fuchs (Cylib), for electric vehicle batteries, the timeline for returns is uncertain; early fleets are lasting longer than expected, delaying the recycling ramp-up. Opelt concluded his presentation with a pragmatic message: “The storm of batteries is coming, but if you build capacity too early, plants will sit empty”, arguing timing is critical.

Across the EU, roughly 300,000 tonnes of batteries enter the market annually. Collection rates for household batteries account for approximately 50%. Many still end up in mixed waste streams or embedded in consumer products. Lithium-ion batteries, now almost omnipresent in common electronics, pose fire hazards during transport and processing.

Industry response

Saubermacher announced the opening of what Andreas Opel called “Europe’s most modern recycling plant” early next year. The facility will process 50,000 tonnes of batteries annually, using AI-driven sorting to achieve 99% accuracy and advanced fire protection systems.

Cylib, represented by Verena Fuchs, is scaling up its proprietary water-based recycling process, which recovers lithium and graphite with 90% efficiency and an 80% lower carbon footprint compared to conventional methods. After validating its technology through more than 35 industrial projects, the company is preparing its first large-scale plant in Germany, capable of processing feedstock equivalent to 140,000 EV batteries per year. Cylib’s approach reduces chemical use, recirculates water and produces high-purity raw materials, aiming to meet EU targets on recycled content.

“If you don’t get 99% quality in sorting, you will never get raw material purity for reuse,” Opel said, underlining the technical complexity of the task – a challenge numerous members of the Cluster Hub are currently addressing.

EU-funded R&I , collaboration and strategy

Eleonora Cali (Rina Consulting), speaking for the Materials for Batteries Hub underlined that circularity cannot be achieved in isolation – a central idea that generated the hub in the first place. Twenty minutes proved to be a challenge to deliver a presentation of each of the 24 members of the hub. The platform connects projects working on different cross-sectorial aspects of the battery value chain, from battery passports, automated dismantling, to reverse logistics and material recovery. Eleonora brought concrete examples how EU-funded projects like BATRAW, FREE4LIB, CICERO, RENOVATE, RESPECT and GR4FITE3 address these aspects hands-on.

The other cluster, titled Circular Battery, presented by Jefferson Palas (EURECAT), introduced other EU-funded initiatives: BatteReverse, RECIRCULATE, REBELION and REINFORCE, each addressing Europe’s end-of-life battery challenge. Similar to the Materials for batteries Hub, Circular Battery focuses on similar topics: standardising dismantling processes, improving safety during handling and transport, and creating digital tools like battery passports for traceability. Key innovations include automated dismantling, second-life models and protocols to reduce fire risks.

Speakers called for:

- accelerated permitting for recycling infrastructures. In China, you can build a recycling plant in six months. In Europe, six months is not even enough to submit a permit,” Opel warned.

- enforcement of design-for-recycling standards in new battery regulations.

- support for industrial scale-up through funding but also simplified regulation.

- call to impose all possible measures to prevent black mass from exiting Europe, already reinforced by its recent classification as hazardous waste.

Probably one of the messages we take with us and integrate it to our initiatives’ objectives is that policies like the EU’s Critical Raw Materials Act, Battery Regulation and now recently adopted ReSourceEU provide the framework. What is needed now is execution at speed.

The ENICON 4th Capacity Building Webinar, titled “Critical Raw Materials and Sustainable Metallurgy: Novel Refining Technologies and Advanced Simulation Tools”, will take place online on 8 December.

Registration remains open until 7 December 2025.

Registered participants will receive an email with the link to attend the seminar.

Discover ENICON’s recent advancements in sustainable metallurgy and process simulation

Join us to explore innovative approaches to critical raw materials, electrifying metallurgical processes, and advanced simulation tools for techno-economic and environmental assessment through two high-level expert presentations.

- Mineral and metal criticality in Europe’s energy transition, addressing essential materials and emerging refining technologies like ENICON’s electrifying metallurgy- Prof. Mari Lundström (AALTO University)-(14:00-15:00 CET).

- Innovative tools for process simulation, Techno-economic and environmental assessment – an introduction to the SUPERPRO platform- Assoc. Professor Dr. Dimitris Ipsakis (TUC) (15:00-16:00 CET).

The webinar is addressing undergraduate and graduate students, early-stage researchers and professionals interested in advancing their expertise in sustainable metallurgy and process simulation.

Production of raw materials for batteries from European resources

After Wednesday’s sessions on the EU political agenda at EU Raw Materials Week, which outlined strategic measures to meet industry needs, attention shifted to the annual workshop of the Materials for batteries hub. Now in its 4th edition, the event was co-organised by Horizon Europe projects RELiEF, FREE4LIB, RESPECT and LITHOS. The focus of the workshop, true to its eponymous theme, was tackling one of Europe’s most urgent challenges: securing sustainable raw materials for batteries.

Under the inauguration of Oliver Schenk, Member of the European Parliament, this edition unfolded under the auspices of urgency, regulatory clarity and cross-border collaboration. The MEP called for swift implementation of the Critical Raw Materials Act and the Net Zero Industry Act, stressing the need for rapid permitting and the mobilisation of both public and private investment. “We cannot afford delays,” he warned. “This is about sovereignty.” His remarks were followed by strong appeals for cooperation among mining regions, manufacturing clusters, research centres and recycling hubs to build a resilient European value chain. He urged participants to contribute to upcoming legislative files, including the European Chips Act 2, the Circular Economy Act and the new EU budget, ensuring that the priorities of the battery materials community are embedded in future policies.

Nader Akil, founder of the Cluster Hub and moderator of the first technical session, emphasised on enhancing the dialogue between academia, industry and policy makers in order to ensure that these goals would be reached.

Following up with a presentation of his most recent scientific publication – “Lindy Effect in Hydrometallurgy” [co-authored with Dr. Ir. Peter Tom Jones] – Professor Koen Binnemans provided a frank look at the shortcomings in industrialising battery material innovations. Transferring hydrometallurgical advancements from lab to plant is slow, constrained by economics, regulation and what the authors call “the Lindy effect” – the tendency for established technologies to stand the test of time. Industry tends to favour incremental improvements to existing processes, such as reducing reagent consumption or increasing automation, rather than adopting entirely new chemistries, due to the high risks and costs associated with large-scale change. Launching a debating topic, audience questions shifted to technical and permitting challenges, concluding with the need for incremental innovation and pragmatic timelines.

Download the presentation

Various EU-funded R&I initiatives, members of the Cluster Hub, presented results and findings with the promise to reduce dependency on imports:

Technical session “Mining and recovery”

- Sabrina Hedrich from TU Bergakademie Freiberg detailed the XRACT project’s pilot sites and the integration of digital tools, remote sensing, and bioleaching for selective recovery of metals, with follow-up technical discussion on downstream processing and environmental permitting.

Download XTRACT presentation - LiCORNE, led by Dr. Lourdes Yurramendi (TECNALIA), focuses on lithium recovery and battery-grade material production from European resources. After intensive techno-economic assessments, LiCORNE has established the flowsheets for lithium extraction and processing technologies for diverse streams, such as ores, brines and off-specification cathode material.

Download LiCORNE presentation - CRM-Geothermal, presented by Konstantinos Loupos (INLECOM), has developed an AI-based tool for lithium estimation in geothermal fluids, with features and validation at a UK demonstration site.

Download CRM-geothermal presentation - METALLICO and ENICON, represented by Sonia Matencio (CETAQUA) and Brecht Dewulf (KU Leuven), aim to demonstrate sustainable recovery of battery metals from primary and secondary sources, focusing on process integration, digital tools and circular hydrometallurgy. METALLICO demonstrates five processes for recovering metals such as lithium, copper, cobalt, and manganese from various sources, with a digital tool for simulating process outcomes and pilot-scale validation of key steps like sulphide precipitation, ion exchange, and diffusion dialysis.

Download METALLICO presentation

ENICON targets responsible mining and refining of cobalt and nickel in Europe, developing improved flow sheets for laterites, sulfides, and intermediates, and validating circular hydrometallurgy concepts with high recovery rates and valorisation of mineral residues.

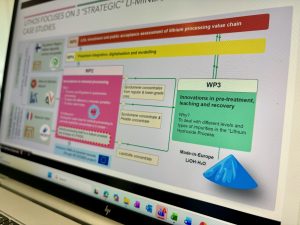

Download ENICON presentation - Thomas Abo Atia (KU Leuven) introduced the LITHOS project which focuses on domestic processing and refining of lithium from European hard rock deposits, integrating advanced mineral processing, digital twins and LCA to reduce environmental impact and support EU supply chain targets. Like many EU-funded initiatives at KU Leuven exploring primary resources, LITHOS introduced the “Lithium paradox” – the latest episode of the documentary co-produced by SIM² KU Leuven (Institute for Sustainable Metals and Minerals) and the Belgian film-maker company Storyrunner.

Download LITHOS presentation - Diego Morillo Martín (LEITAT) presented one of the most mature projects of the hub – RAWMINA, an EU-funded initiative aiming to transform mine waste into resources through scalable bioleaching, alkaline leaching and selective recovery of critical and valuable metals, with pilot-scale demonstrations developed at Cobre las Cruces. The project reported achieving high recovery rates for cobalt, antimony, germanium, tungsten, iron, gold and silver, and validating nanomaterial-based selective recovery and water reuse.

Download RAWMINA presentation

Technical session “Recycling and circularity”

- Thomas Opsomer (ABEE) presented the final results of RELiEF, a project that achieved a reduction in hazardous elements, developed a microwave leaching process with over 95% yield, and produced high-purity lithium carbonate (98.28%); while not yet battery grade materials, recovered lithium carbonate showed promising results in relithiation tests. The lithium carbonate produced was successfully tested in coin and pouch cell formats, demonstrating high reproducibility and performance close to commercial LFP materials. Opsomer emphasised the growing importance of LFP batteries in Europe and the lack of recycling capacity, noting that extended producer responsibility (EPR) regulations now require battery integrators to address recycling, registration, and reporting. This creates both administrative burdens and incentives for recyclers, with recycling fees sometimes reaching 30% of battery unit costs.

Moreover, RELiEF’s “balance sheet” listed its unsolved challenges which include insufficient black mass refining capacity and the upscaling of innovative technologies. On the other hand, opportunities include standardising black mass quality, implementing direct recycling methods and the development of regional ecosystems that connect recyclers, OEMs and policymakers to promote sustainable business models.

Download RELiEF presentation - Alvaro Manjon (TECNALIA) detailed the RHINOCEROS project’s progress in automating battery disassembly, optimising recycling routes and upscaling processes for high recovery rates of battery materials, with a focus on sustainability and safety. The project is transitioning from R&D to construction and commissioning of pilot plants, with detailed engineering completed. Upscaling activities focus on refining, pre-treatment, and qualification of recovered materials for use in new batteries, aiming for TRL 6 and production of tens of kilograms of electrode materials per day. RHINOCEROS integrates circularity and zero-waste strategies, with ongoing validation of recovered materials in prototype batteries.

Download RHINOCEROS presentation - FREE4LIB, presented by Juan Castro Bustamante (CARTIF), combines robotic dismantling, material recovery with a digital battery passport for traceability. The project achieved pilot-scale robotic dismantling, developed advanced state-of-health estimation tools for second-life batteries and implemented multiple pre-treatment and recycling technologies, including pyrolysis, ultrasonic delamination and hydrothermal routes for cathode material recovery. Recovered metals and polymers were reused in new battery packs, including e-bike prototypes, with successful demonstration of material quality and performance. The project also established a pilot line for metal powder atomization and 3D printing of recovered plastics.

Project partners developed a digital passport featuring role-based access, blockchain integration, and QR labelling to enhance traceability and regulatory compliance. The platform will be made available for public access by the end of the project.

Download FREE4LIB presentation - RESPECT, represented by Andrea Locati (Chalmers University), presented the project’s developed flowsheet for solvent extraction and recovery of manganese, cobalt and nickel from black mass, achieving high purity and minimal cross-contamination. The recovered salts were used by CEA to produce cathode active materials, with up to 20% recycled content in electrodes, showing how the targets proposed by the Critical Raw Materials Act and the Battery Regulation are achievable. The approach allows for flexibility in product output, enabling adaptation to different NMC chemistries or other applications. Challenges include the complexity of operations, need for recirculation to minimise losses and adjusting process parameters to variable feed compositions.

The conclusions of the RESPECT presentation emphasised the need to propose clear definitions of battery-grade materials and the importance of aligning process outputs with regulatory requirements.

Download RESPECT presentation

Debating industrial integration, collaboration and European competitiveness

Two panels framed the bigger picture. The first one, chaired by Nader Akil (PNO Innovation Belgium), addressed scaling up technologies and reducing mining’s environmental footprint, with strong emphasis on AI and data-driven processes.

- Panellists -Sabrina Hedrich, Kostas Loupos and Diego Morillo Martin – listed the integration of digital tools, remote sensing and bioleaching as core to reducing mining’s environmental footprint, with validation across multiple pilot sites.

- The value of AI in resource estimation depends on the availability and integration of diverse data sources, with more data enabling better predictions and process optimisation.

- Scalability was discussed in terms of achieving higher TRL levels, with bioleaching and selective recovery identified as critical steps, and the need for further work on final product purity and process integration for marketable outputs.

- Audience questions addressed the impact of strict regulations on competitiveness, the need for closer industry-research collaboration, and the lack of dedicated funding mechanisms for critical raw material projects, with suggestions for policy recommendations and strategic investment.

The second panel discussion, moderated by Olga Henkele (Kellen) and inviting Joana Gouveia (INEGI), Sam Hoefman (EURICE) and Dr. Florian Anderhuber (Euromines) as guests, reflected on how Europe can progress from promising battery recycling innovations toward a more operational and industrial circular economy. Speakers agreed that while European research projects are generating strong technical evidence, several barriers still remain before a fully closed loop can be achieved. It addressed policy and market dynamics:

- Barriers to circularity: panelists emphasised the need for economically viable recycling in Europe and reducing regulatory burdens on recyclers. Other recommendations placed the time gap between research and industrial implementation, as well as cross-collaboration communication channels between academia, industry and policy makers as drivers of European industrial competitiveness.

- Florian Anderhuber highlighted lengthy permitting processes for new technologies and the lack of demand-side measures such as recycled content requirements. He stressed the need for financial support and market incentives to stimulate recycling and primary sourcing within Europe.

- Panellists discussed the importance of feeding clear evidence from EU-funded projects into policy making, setting clear project objectives, and considering the life cycle of projects from inception to exploitation. Joanna Gouveia, while emphasising on the LCA approaches in project, provided a direct example from the RELiEF project, where policy definitions limited the classification of secondary lithium, suggesting the need for broader definitions.

Attendance reflected growing interest across Europe’s battery materials value chain. Out of 151 registered participants, 70 joined the workshop online, while approximately 50 attended the workshop in person. The audience was diverse: academia and research institutes accounted for the largest share, followed by industry players, consultancies, and policy representatives. This mix underlined the workshop’s role as a bridge between research and innovation on one hand and industry and policymaking on the other. By bringing together stakeholders from these different sectors, the workshop enhanced dialogue, knowledge exchange, and potential collaboration opportunities across the European battery materials ecosystem.

Join the 2nd Capacity-Building Webinar of LITHOS project, focused on low-cost and sustainable routes for developing new pathways for processing and refining lithium in Europe.

The webinar features two high-level presentations followed by a brief Q&A:

“Strategies, Opportunities, and Challenges for the Development of LCIs for Battery Raw Materials” (11:00–12:00 CET)

Dr. Aina Mas Fons — Research Engineer, BRGM (France)

An overview of methods, opportunities and challenges for developing life-cycle inventories (LCIs) for battery raw materials

“LITHOS WP2: Preliminary findings on characterisation and beneficiation test work”

Dr. Jussi Liipo — Director, Geometallurgy & Mineralogy (12:00–13:00CEΤ )

Annukka Aaltonen Msc, Technology Manager, Metso (Finland)

Presentation of initial test results and early insights into mineral characterisation and beneficiation approaches being tested within LITHOS.

The webinar is addressed to:

- undergraduate and graduate students

- early-stage researchers

- professionals interested in advancing their expertise in the fields of mineral processing and LCIs

Interested participants are invited to register here.

Registered participants will receive an email with the link for the webinar.

Save the date on Friday 28th of November 11:00–13:00 CET / Horizon Europe CICERO is organising the 2nd Capacity Building Webinar entitled “Advances in Circular Hydrometallurgy – Insights from the HE CICERO Project”

Discover the latest insights and innovations in circular hydrometallurgy through two high-level presentations:

- The 12 Principles of Circular Hydrometallurgy -Professor Koen Binnemans -KU-Leuven (11:00–12:00 CET)

- Electrowinning of Metals from Aqueous Solutions: The Potential of Methane Sulfonic Acid as Electrolyte -Siri Marie Skaftun – SINTEF (12:00–13:00 CET)

This capacity building webinar aims to strengthen knowledge and skills in circular hydrometallurgy.

Target audience

It is addressed to undergraduate and graduate students, early-stage researchers, and professionals interested in advancing their expertise in circular hydrometallurgy.

Interested parties are invited to register here by 27/11/2025.

Registered participants will receive an email with the link for the seminar.

This workshop will examine how Life Cycle Assessment (LCA) can support emerging processes in minerals and metals production at mid/low Technology Readiness Levels (TRL 4 – 7).

Conducting LCAs for lab or pilot scale processes presents unique challenges, from data gaps and high uncertainty to the difficulty of scaling-up results to industrial applications. Drawing on examples from Horizon Europe projects, the session will highlight how these challenges are being addressed and how early-stage LCAs can provide valuable insights to guide process development, scale-up, and decision-making.

Special thanks to Università/Politecnico di Torino organising this webinar, and representatives of BRGM (CICERO project) and TUC (LITHOS/EXCEED projects) involved in the programme.

Documentary screening and a panel discussion at Cinema Aventure in Brussels on 17th November 2025 (18:00-20:00).

The LITHOS project is co-organising an event on the night before the kick off of EU Raw Materials Week which will also include a high level expert panel.

The event includes the screening of Europe’s Lithium Paradox documentary, which will be followed by a panel discussion addressing the role of lithium in energy transition, covering its environmental, economic, industrial, geopolitical and social dimensions, especially in the light of the recent export restrictions by China on lithium, graphite and rare earth materials and technology.

© visual: SIM2 KU LEUVEN

Hybrid event | 📍NH Brussels Carrefour de l’Europe | Rue Marche aux Herbes – Grasmarkt Straat, 110, 1000 Brussels, Belgium

60 in-person seats (first come, first served) | Unlimited online participation

This high-impact webinar, hosted by the Cluster Hub “Production of Raw Materials for Batteries from European Resources”, brings together over 20 EU-funded projects and 120+ organisations to present concrete results from across the battery raw materials value chain. The 2025 edition of the cluster workshop is co-organised by projects RELiEF, FREE4LIB, RESPECT and LITHOS.

Whether you’re in research, industry, or policy, this webinar will show you:

- Which technological paths are proving effective, with data from Horizon Europe projects

- Cross-sector dialogues featuring industry leaders, researchers and policy makers

- Challenges and solutions in scaling up, environmental performance and social acceptance

The session is designed to inform and inspire the research community, industrial innovators and policy shapers working toward a competitive, circular and resilient European battery ecosystem.

Why attend?

To see what’s working, where innovation is heading and how collaborative R&I is shaping Europe’s strategic autonomy in battery raw materials.

Participation details

Please note that in-person attendance is limited to 60 participants. Once this number is reached, physical registration will be closed. Online participation will remain available for those who wish to attend remotely.

Website managed by PNO Innovation

Website managed by PNO Innovation