Production of raw materials for batteries from European resources

After Wednesday’s sessions on the EU political agenda, which outlined strategic measures to meet industry needs, attention shifted to the annual workshop of the Materials for batteries hub. Now in its 4th edition, the event was co-organised by Horizon Europe projects RELiEF, FREE4LIB, RESPECT and LITHOS. The focus of the workshop, true to its eponymous theme, was tackling one of Europe’s most urgent challenges: securing sustainable raw materials for batteries.

Under the inauguration of Oliver Schenk, Member of the European Parliament, this edition unfolded under the auspices of urgency, regulatory clarity and cross-border collaboration. The MEP called for swift implementation of the Critical Raw Materials Act and the Net Zero Industry Act, stressing the need for rapid permitting and the mobilisation of both public and private investment. “We cannot afford delays,” he warned. “This is about sovereignty.” His remarks were followed by strong appeals for cooperation among mining regions, manufacturing clusters, research centres and recycling hubs to build a resilient European value chain. He urged participants to contribute to upcoming legislative files, including the European Chips Act 2, the Circular Economy Act and the new EU budget, ensuring that the priorities of the battery materials community are embedded in future policies.

Nader Akil, founder of the Cluster Hub and moderator of the first technical session, emphasised on enhancing the dialogue between academia, industry and policy makers in order to ensure that these goals would be reached.

Following up with a presentation of his most recent scientific publication – “Lindy Effect in Hydrometallurgy” [co-authored with Dr. Ir. Peter Tom Jones] – Professor Koen Binnemans provided a frank look at the shortcomings in industrialising battery material innovations. Transferring hydrometallurgical advancements from lab to plant is slow, constrained by economics, regulation and what the authors call “the Lindy effect” – the tendency for established technologies to stand the test of time. Industry tends to favour incremental improvements to existing processes, such as reducing reagent consumption or increasing automation, rather than adopting entirely new chemistries, due to the high risks and costs associated with large-scale change. Launching a debating topic, audience questions shifted to technical and permitting challenges, concluding with the need for incremental innovation and pragmatic timelines.

Download the presentation

Various EU-funded R&I initiatives, members of the Cluster Hub, presented results and findings with the promise to reduce dependency on imports:

Technical session “Mining and recovery”

- Sabrina Hedrich from TU Bergakademie Freiberg detailed the XRACT project’s pilot sites and the integration of digital tools, remote sensing, and bioleaching for selective recovery of metals, with follow-up technical discussion on downstream processing and environmental permitting.

Download XTRACT presentation - LiCORNE, led by Dr. Lourdes Yurramendi (TECNALIA), focuses on lithium recovery and battery-grade material production from European resources. After intensive techno-economic assessments, LiCORNE has established the flowsheets for lithium extraction and processing technologies for diverse streams, such as ores, brines and off-specification cathode material.

Download LiCORNE presentation - CRM-Geothermal, presented by Konstantinos Loupos (INLECOM), has developed an AI-based tool for lithium estimation in geothermal fluids, with features and validation at a UK demonstration site.

Download CRM-geothermal presentation - METALLICO and ENICON, represented by Sonia Matencio (CETAQUA) and Brecht Dewulf (KU Leuven), aim to demonstrate sustainable recovery of battery metals from primary and secondary sources, focusing on process integration, digital tools and circular hydrometallurgy. METALLICO demonstrates five processes for recovering metals such as lithium, copper, cobalt, and manganese from various sources, with a digital tool for simulating process outcomes and pilot-scale validation of key steps like sulphide precipitation, ion exchange, and diffusion dialysis.

Download METALLICO presentation

ENICON targets responsible mining and refining of cobalt and nickel in Europe, developing improved flow sheets for laterites, sulfides, and intermediates, and validating circular hydrometallurgy concepts with high recovery rates and valorisation of mineral residues.

Download ENICON presentation - Thomas Abo Atia (KU Leuven) introduced the LITHOS project which focuses on domestic processing and refining of lithium from European hard rock deposits, integrating advanced mineral processing, digital twins and LCA to reduce environmental impact and support EU supply chain targets. Like many EU-funded initiatives at KU Leuven exploring primary resources, LITHOS introduced the “Lithium paradox” – the latest episode of the documentary co-produced by SIM² KU Leuven (Institute for Sustainable Metals and Minerals) and the Belgian film-maker company Storyrunner.

Download LITHOS presentation - Diego Morillo Martín (LEITAT) presented one of the most mature projects of the hub – RAWMINA, an EU-funded initiative aiming to transform mine waste into resources through scalable bioleaching, alkaline leaching and selective recovery of critical and valuable metals, with pilot-scale demonstrations developed at Cobre las Cruces. The project reported achieving high recovery rates for cobalt, antimony, germanium, tungsten, iron, gold and silver, and validating nanomaterial-based selective recovery and water reuse.

Download RAWMINA presentation

Technical session “Recycling and circularity”

- Thomas Opsomer (ABEE) presented the final results of RELiEF, a project that achieved a reduction in hazardous elements, developed a microwave leaching process with over 95% yield, and produced high-purity lithium carbonate (98.28%); while not yet battery grade materials, recovered lithium carbonate showed promising results in relithiation tests. The lithium carbonate produced was successfully tested in coin and pouch cell formats, demonstrating high reproducibility and performance close to commercial LFP materials. Opsomer emphasised the growing importance of LFP batteries in Europe and the lack of recycling capacity, noting that extended producer responsibility (EPR) regulations now require battery integrators to address recycling, registration, and reporting. This creates both administrative burdens and incentives for recyclers, with recycling fees sometimes reaching 30% of battery unit costs.

Moreover, RELiEF’s “balance sheet” listed its unsolved challenges which include insufficient black mass refining capacity and the upscaling of innovative technologies. On the other hand, opportunities include standardising black mass quality, implementing direct recycling methods and the development of regional ecosystems that connect recyclers, OEMs and policymakers to promote sustainable business models.

Download RELiEF presentation - Alvaro Manjon (TECNALIA) detailed the RHINOCEROS project’s progress in automating battery disassembly, optimising recycling routes and upscaling processes for high recovery rates of battery materials, with a focus on sustainability and safety. The project is transitioning from R&D to construction and commissioning of pilot plants, with detailed engineering completed. Upscaling activities focus on refining, pre-treatment, and qualification of recovered materials for use in new batteries, aiming for TRL 6 and production of tens of kilograms of electrode materials per day. RHINOCEROS integrates circularity and zero-waste strategies, with ongoing validation of recovered materials in prototype batteries.

Download RHINOCEROS presentation - FREE4LIB, presented by Juan Castro Bustamante (CARTIF), combines robotic dismantling, material recovery with a digital battery passport for traceability. The project achieved pilot-scale robotic dismantling, developed advanced state-of-health estimation tools for second-life batteries and implemented multiple pre-treatment and recycling technologies, including pyrolysis, ultrasonic delamination and hydrothermal routes for cathode material recovery. Recovered metals and polymers were reused in new battery packs, including e-bike prototypes, with successful demonstration of material quality and performance. The project also established a pilot line for metal powder atomization and 3D printing of recovered plastics.

Project partners developed a digital passport featuring role-based access, blockchain integration, and QR labelling to enhance traceability and regulatory compliance. The platform will be made available for public access by the end of the project.

Download FREE4LIB presentation - RESPECT, represented by Andrea Locati (Chalmers University), presented the project’s developed flowsheet for solvent extraction and recovery of manganese, cobalt and nickel from black mass, achieving high purity and minimal cross-contamination. The recovered salts were used by CEA to produce cathode active materials, with up to 20% recycled content in electrodes, showing how the targets proposed by the Critical Raw Materials Act and the Battery Regulation are achievable. The approach allows for flexibility in product output, enabling adaptation to different NMC chemistries or other applications. Challenges include the complexity of operations, need for recirculation to minimise losses and adjusting process parameters to variable feed compositions.

The conclusions of the RESPECT presentation emphasised the need to propose clear definitions of battery-grade materials and the importance of aligning process outputs with regulatory requirements.

Download RESPECT presentation

Debating industrial integration, collaboration and European competitiveness

Two panels framed the bigger picture. The first one, chaired by Nader Akil (PNO Innovation Belgium), addressed scaling up technologies and reducing mining’s environmental footprint, with strong emphasis on AI and data-driven processes.

- Panellists -Sabrina Hedrich, Kostas Loupos and Diego Morillo Martin – listed the integration of digital tools, remote sensing and bioleaching as core to reducing mining’s environmental footprint, with validation across multiple pilot sites.

- The value of AI in resource estimation depends on the availability and integration of diverse data sources, with more data enabling better predictions and process optimisation.

- Scalability was discussed in terms of achieving higher TRL levels, with bioleaching and selective recovery identified as critical steps, and the need for further work on final product purity and process integration for marketable outputs.

- Audience questions addressed the impact of strict regulations on competitiveness, the need for closer industry-research collaboration, and the lack of dedicated funding mechanisms for critical raw material projects, with suggestions for policy recommendations and strategic investment.

The second panel discussion, moderated by Olga Henkele (Kellen) and inviting Joana Gouveia (INEGI), Sam Hoefman (EURICE) and Dr. Florian Anderhuber (Euromines) as guests, reflected on how Europe can progress from promising battery recycling innovations toward a more operational and industrial circular economy. Speakers agreed that while European research projects are generating strong technical evidence, several barriers still remain before a fully closed loop can be achieved. It addressed policy and market dynamics:

- Barriers to circularity: panelists emphasised the need for economically viable recycling in Europe and reducing regulatory burdens on recyclers. Other recommendations placed the time gap between research and industrial implementation, as well as cross-collaboration communication channels between academia, industry and policy makers as drivers of European industrial competitiveness.

- Florian Anderhuber highlighted lengthy permitting processes for new technologies and the lack of demand-side measures such as recycled content requirements. He stressed the need for financial support and market incentives to stimulate recycling and primary sourcing within Europe.

- Panellists discussed the importance of feeding clear evidence from EU-funded projects into policy making, setting clear project objectives, and considering the life cycle of projects from inception to exploitation. Joanna Gouveia, while emphasising on the LCA approaches in project, provided a direct example from the RELiEF project, where policy definitions limited the classification of secondary lithium, suggesting the need for broader definitions.

Attendance reflected growing interest across Europe’s battery materials value chain. Out of 151 registered participants, 70 joined the workshop online, while approximately 50 attended the workshop in person. The audience was diverse: academia and research institutes accounted for the largest share, followed by industry players, consultancies, and policy representatives. This mix underlined the workshop’s role as a bridge between research and innovation on one hand and industry and policymaking on the other. By bringing together stakeholders from these different sectors, the workshop enhanced dialogue, knowledge exchange, and potential collaboration opportunities across the European battery materials ecosystem.

Join the 2nd Capacity-Building Webinar of LITHOS project, focused on low-cost and sustainable routes for developing new pathways for processing and refining lithium in Europe.

The webinar features two high-level presentations followed by a brief Q&A:

“Strategies, Opportunities, and Challenges for the Development of LCIs for Battery Raw Materials” (11:00–12:00 CET)

Dr. Aina Mas Fons — Research Engineer, BRGM (France)

An overview of methods, opportunities and challenges for developing life-cycle inventories (LCIs) for battery raw materials

“LITHOS WP2: Preliminary findings on characterisation and beneficiation test work”

Dr. Jussi Liipo — Director, Geometallurgy & Mineralogy (12:00–13:00CEΤ )

Annukka Aaltonen Msc, Technology Manager, Metso (Finland)

Presentation of initial test results and early insights into mineral characterisation and beneficiation approaches being tested within LITHOS.

The webinar is addressed to:

- undergraduate and graduate students

- early-stage researchers

- professionals interested in advancing their expertise in the fields of mineral processing and LCIs

Interested participants are invited to register here.

Registered participants will receive an email with the link for the webinar.

The RELiEF project (Horizon Europe GA 101069789), one of the most mature EU-funded projects in the Cluster Hub “Production of raw materials for batteries from European resources”, has published an open-access study evaluating the coherence of recent EU policies shaping the battery value chain.

The study focuses on the EU’s Green Deal Industrial Plan and related legislative pillars, such as:

- the Net-Zero Industry Act: aims for 40% of clean tech needs to be met by EU production by 2030.

- the Critical Raw Materials Act: seeks to secure EU’s supply of critical raw materials (lithium, cobalt).

- the EU Battery Regulation 2023: introduces strict lifecycle rules to promote circularity and sustainability.

Partners from RELiEF project engaged in discussions with various stakeholders across the battery value chain in Europe to understand the sentiment and the level of perception of these regulations. Their methodology circled around two main questions:

- Do these initiatives complement or contradict each other?

- How do stakeholders perceive these regulations and their feasibility?

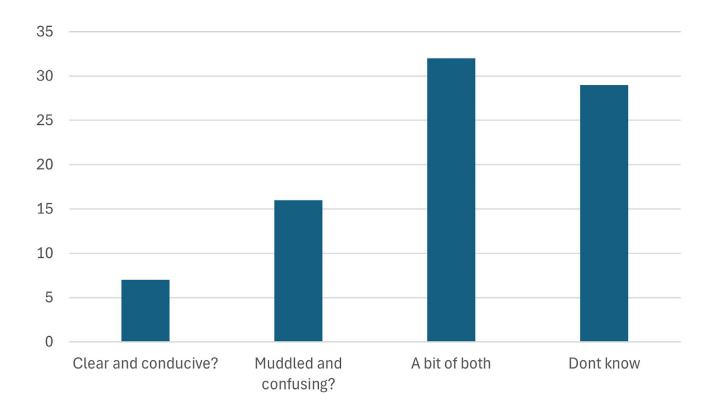

Perception of the EU regulatory climate. ©Research article “Stakeholder Perspectives on EU Regulatory Frameworks: Navigating Critical Raw Materials, Battery Innovation and Recycling Challenges” [web: https://open-research-europe.ec.europa.eu/articles/5-104]

These interactions allowed stakeholders to express additional concerns about skills shortages and social acceptance. Cutting red tape and streamlined permitting remain road blockers for projects both in mining and recycling. Targets such as the NZIA’s 40 % clean tech production and CRMA’s 10 % domestic sourcing were seen as ambitious, while others, like the 15 % recycling goal, were considered feasible and relaxed. The call for more balanced policy objectives and realistic targets was a recurring topic.

The Cluster Hub’s annual workshops and bilateral meetings between projects created opportunities for the ReLIEF partners to engage with a variety of stakeholders in the battery sector. It facilitated collaboration and discussions between EU-funded projects, revealing a shared sentiment about the EU regulatory ecosystem and common barriers that risk slowing EU’s industrial competitiveness.

The webinar Africa ‘s role in CRM mining and refining ” co-organised by CICERO, LITHOS, ENICON, EXCEED, AVANTIS projects will take place online on 4th of June 2025.

The seminar will feature two insightful presentations from high level experts from Africa, Everjoy Muchefa Researcher & Process Engineer from University of Johannesburg and Professor Harmony Musiyarira, Executive Dean of the Faculty of Engineering and the Built Environment at Namibia University of Science and Technology (NUST).

The presentations dedicated to critical aspects of the mining sector in Africa, provide insightful analysis. The first presentation offers a reflective examination of artisanal and small-scale mining of lithium-bearing minerals. It elucidates the current practices, socio-economic consequences, and regulatory framework governing this sector. The second presentation covers the broader prospects and challenges associated with sustainable mining practices in the region. It addresses environmental concerns, governance dilemmas, and the and the need for responsible resource management.

These sessions aim to foster a deeper understanding of Africa’s complex mining dynamics and stimulate dialogue on sustainable and inclusive mining pathways.

If you are interested, please register at the following link, until 2/6/2025: link registration.

The registered participants will receive an email with the Zoom link.

The webinar is co-organised by ENICON, EXCEED, CICERO, AVANTIS, LITHOS projects and will take place online on 29th of May 2025.

The seminar will prioritize international collaboration to foster global cooperation in CRM innovation and policy development. Two high level experts from USA – Prof. Z. Agioutantis (University of Kentucky) and Australia – Prof. G. Barakos (Curtin University) will emphasize the global perspective of CRM mining and research technologies.

If you are interested, please register at the following link, until 27/5/2025. Registered participants will receive an email with the Zoom link.

Mark your calendars for 12 December 2024, when the third edition of the annual workshop of the Cluster Hub “Production of raw materials for batteries from European resources”.

The event will be hybrid. It will take place in Brussels, at Thon Hotel EU, Rue de la Loi 75, 1040. The number of seats is limited, and will be assigned on a first come first served policy. However, interested participants can attend online, upon registration with the LINK.

Batteries have been around for centuries, with successive technological advancements leading to major electrical leaps: from the early rise of telegraphs and telephones to the modern life ‘commodities’ such as consumer electronics, electric vehicles and healthcare.

Despite a policy context incentivising European stakeholders to build a climate-neutral society, this ambitious plan hinges on the electrification of two key industrial sectors – transport and energy – accounting together for 76 % of the EU’s GHG emissions. To meet the rising demand of batteries, Europe is looking for alternatives to reduce its dependency on battery imports and enhance its competitiveness in the global battery market. This push to re-industrialise Europe’s battery manufacturing is supported by technological advancements.

The Cluster Hub ‘Production of raw materials for batteries from European resources’ is organising the third edition of its annual workshop on 12 December 2024. With each edition, the hub plans to provide a comprehensive overview of the most promising technologies engaged in the production of raw materials for batteries, from raw materials mining to recycling.

Additional to the technical sessions which will present the most recent results from the member projects included in the EU-funded hub, the workshop will set off with an incursion across the European policy environment, introduced by representatives of the European Commission and BEPA.

Who is the event dedicated to?

Any stakeholder interested in the R&I context in the battery sector, whether a representative of industry, cross-sector activities, research community or a policy-maker, is welcome to participate. Each session presenting results will be concluded with a dedicated Q&A slot, where participating attendees are invited to address questions.

Beyond presenting the latest results accomplished by our member projects, the event plans to open the stage to challenging discussions, ultimately aiming to identify opportunities for value creation within the European battery sector.

Disclaimer

The event will be recorded (audio & video) and pictures will be taken. Should participants have any objections, these should be addressed to the organisers.

Registration

The event is hybrid. On site participation is limited to the conference room capacity. Seats are limited and allocated to the first 40 participants expressing interest.

Register for on site participation

The event can also be attended online, using Teams platform. Registration is mandatory.

Register here for online participation

The RAWMINA Final Conference is an event focusing on the recovery of Critical Raw Materials (CRM) from mine waste within a circular economy framework. This two-day conference, held between 22 and 23 October, at the Casa de la Convalescència, Hospital Sant Pau in Barcelona, Spain, brings together leading researchers, industry experts, policymakers, and innovators to explore cutting-edge advancements in CRM recovery.

What to expect

- Tech Deep-dive Sessions

- Round Table Discussions

- Early Researchers’ Symposium

- Matchmaking Sessions & Funding Opportunities Workshops

- Clustering Sessions

This conference is a must-attend for anyone interested in groundbreaking CRM-recovery technologies, sustainable mining practices, or networking with key industry players.

Registrations are open until 8 October. Secure your spot now!

Immediately after its M24 Consortium meeting, the LiCORNE project will co-organise the first edition of the Symposium on Direct Lithium Extraction (SDLE). The event is hosted between 17 and 18 October 2024 by Karlsruhe Institute of Technology (KIT).

This symposium will delve into the latest advancements and innovative technologies in the field of direct lithium extraction (DLE), fostering collaboration and knowledge exchange to drive forward this critical sector.

Topical Overview:

- Liquid / solid Li extraction technologies

- Membrane & precipitation technologies

- Conversion to battery

- Electrochem. Li extraction & Desalination Technologies

- Concentration & Purification of Li-brines

The symposium will feature additional

- industry sessions

- poster sessions, where interested parties can submit abstracts

On Thursday, 16 November, during the 2023 edition of the Raw Materials Week, the twelve EU funded projects that constitute the Cluster Hub ‘Materials for batteries’ gathered for their annual event in Brussels.

The Cluster Hub has been initiated last year during the 7th edition of the Raw Materials Week. The main objective of the meeting was to meet and discuss the latest developments in the participating projects as well as the new challenges and opportunities discovered through the projects’ lifetime. Nader Akil, Operations Manager at PNO Innovation, inaugurated this second edition outlining the motivation behind the hub’s establishment. He underlined the positive reception and sustained interest from various stakeholders keen on joining this initiative.

Discover and/or rediscover the first edition of the Cluster Hub workshop

Co-organised by RELiEF, EXCEED, ENICON and RAWMINA, the event was also the opportunity to welcome the four new members of the Cluster (EXCEED, RAWMINA, METALLICO and CRM-geothermal). the workshop gathered nearly 100 organisations driving the production and the recycling of raw materials for battery applications from primary and secondary resources.

Building on the initial objective of creating an environment that could foster knowledge exchange on different approaches for the recycling and recovery for battery applications, the event focused on three major topics that depict the transversality characterising the projects: the raw materials through research and science, the roles and challenges of industry and market for raw materials, and the raw materials under the scope of sustainability, durability and social acceptance. During this annual meeting, an interactive session led by Anish Patil from TechConcepts and representing the RELiEF project had the objective of Mapping the European battery material recycling landscape – more details to be found below, in the section referring to the interactive session.

Research and science unlocking new opportunities in raw materials

The first session was moderated by Sonia Matencio from LEITAT, representing the RAWMINA project. This session had the objective of discussing the raw materials through research and science, under the scopes of mining, refining, processing as well as the battery data. Sonia introduced this topic under the scope of RAWMINA, explaining the integrated innovative pilot system for Critical Raw Materials recovery from mine waste in a circular economy context. To this end, Christophe Aucher, from LEITAT as well, highlighted the need on an open battery passport system to better reflect and account for any adaptations that might be required due to the changing regulatory landscape.

Sonia welcomed afterward Brecht Dewulf from KU LEUVEN and representing ENICON, who discussed the sustainable processing of Europe’s low grade sulphidic and lateritic Ni/Co ores and tailings into battery grade metals. The idea behind this was to show all the potential of Ni/Co resources for Europe.

Xochitl Dominguez from VITO concentrated her speech on gas-diffusion electrocrytallisation (GDEx), a crucial topic for the projects LiCORNE and RHINOCEROS she works with. GDEx is an electrochemical process of reactive precipitation of metals in solution with oxidising or reducing agents produced in-situ by the electrochemical reduction of a gas, in a gas-diffusion electrode. This was followed by Katrin Kieling from GFZ Potsdam, working there for the CRM-geothermal project and shortly explained the challenges of extracting critical raw materials from geothermal fluids. To conclude this first session, Sandra Pavón from Fraunhofer IKTS explained the demonstration of battery metals recovery from primary and secondary resources through a sustainable processing methodology in the METALLICO project.

Discover presentations from Session 1

Insights from stakeholder perspectives: Interactive session on key EU Policies and priorities

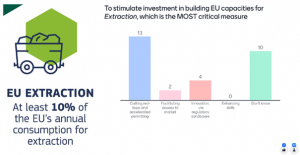

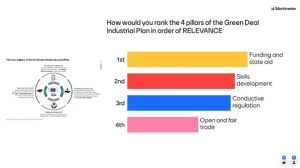

The annual meeting followed its course with an interactive session led by Anish Patil, which scrutinised stakeholders’ perspectives on the Green Deal Industrial Plan, Net Zero Industrial Act, Critical Raw Materials Act and the European Battery Regulation 2023. Mentimeter facilitated this interactive session, engaging the audience to explore how these policies intersect, complement each other, and identify critical measures and incentives for achieving their objectives.

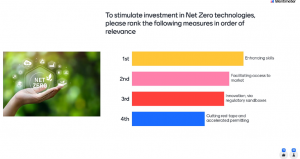

Over 30 persons participated in the live-poll proposed, which results display the priority to be set on funding and state aid regarding ranking the four pillars of the Green Deal Industrial Plan in order of relevance (followed by skills development, conductive regulation, and open and fair trade). Another major topic regarding the stimulation of investment in net Zero technologies, the majority of answers placed the ‘enhanced skills’ as first priority, shortly followed by facilitating the access to the market.

Lastly, the participants were divided regarding the critical measures to implement in the EU to stimulate investment in building domestic capacities for extraction of critical raw materials (CRMs). Although the majority opted for ‘cutting red-tape and accelerated permitting’, approximately half of the answers evoked uncertainty, which emphasised one more time the need to engage with policy makers as external stakeholders in all projects.

Navigating the nexus: industry challenges, market dynamics, social acceptance and sustainability

This interactive workshop was followed by two sessions, which aimed at discussing the challenges and opportunities of raw materials within the frame of industry and market, as well as the social acceptance, sustainability, and durability.

Alan Gonzalez from PNO Innovation Begium, representing LiCORNE, moderated the industry part, whereas Sam Hoefman from RELiEF moderated the last session on social acceptance, sustainability, and durability. Distinguished panellists took the stage to engage in debates on various topics.

Edvarts Emerson, Production and Testing Engineer at Watt4Ever, presented his work on the benchmark depository of 2nd life use of lithium in batteries, acceptance criteria and guidelines, work developed within the RHINOCEROS project. Benjamin Wilson, representing the RESPECT Project, displayed Aalto University’s work advancing efficient, sustainable, innovative and safe battery recycling processes in the EU. Laura Kainiemi from LUT University, representing the RELiEF Project, Konstantinos Komnitsas from the Technical University of Crete (TUC), on behalf of EXCEED, and Vitor Correia from INTRAW for the CRM-geothermal project, collectively debated the role and impact of social acceptance among affected communities, the importance of triggering new dialogues on responsible mining activities, and the joint involvement of regional, national and European authorities, academia, industry partners, and citizens in shaping these initiatives.

A big thank you to all participants for this co-creative and very constructive and inspiring meeting.

Discover presentations from Session 2

Discover presentations from Session 3

Snapshots from the second edition of the Cluster Hub workshop “Production of raw materials for batteries from European resources”

The ENICON Horizon Europe funded research project, organizes the 1st Capacity Building Seminar, on the 2nd and 3rd of October 2023. The seminar will take place at the Technical University of Crete’s Campus, Greece, in a hybrid format.

The target group of the seminar involves mainly graduate and post graduate students and early stage researchers, however all students and researchers in topics related to ENICON’s objectives are welcome.

The seminar will take place at the Technical University of Crete’s Campus, Greece, in a hybrid format. Four lectures will be given by Prof. Koen Binnemans (KU Leuven), Prof. M. Konsolakis (TUC), Dr. Arne Peys (VITO) and Dr. George Bartzas (ΤUC), who are experts in their fields.

A Zoom link will be provided to the registered participants after the closing of the registration period.

The detailed program is the following:

| Lecturer | Lecture | Date |

| Prof. Koen Binnemans (KU Leuven) | The 12 Principles of Circular Hydrometallurgy | 2/10/2023

10.00 AM – 12.00 PM (local time, UTC +2) |

| Dr. Arne Peys (VITO) | Matrix valorization of mining and process residues: what to do with the rest of the material after extracting 1% of valuable metals | 2/10/2023

14.00 PM – 16.00 PM (local time, UTC +2) |

| Prof. M. Konsolakis (TUC) | Rational design of Ni- and Co-based catalysts for energy transition and environmental sustainability | 3/10/2023

10.00 AM – 12.00 PM (local time, UTC +2) |

| Dr. George Bartzas (ΤUC) | Environmental challenges of nickel metal industry through life cycle assessment | 3/10/2023

14.00 PM – 16.00 PM (local time, UTC +2) |

Website managed by PNO Innovation

Website managed by PNO Innovation